crush test ect vs burst strength ups|burst vs ect : wholesaling When determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in pounds and is related to the handling durability of the box material. Ofertas Oi TV Pós-Pago, não cumulativas válidas de 01/03/2.

{plog:ftitle_list}

webFicha técnica. Comentários. Notícias. Assista Agora. 14 - Não recomendado para menores de 14 anos 202 minutos. A sua mensagem política sobre as relações raciais mudou .

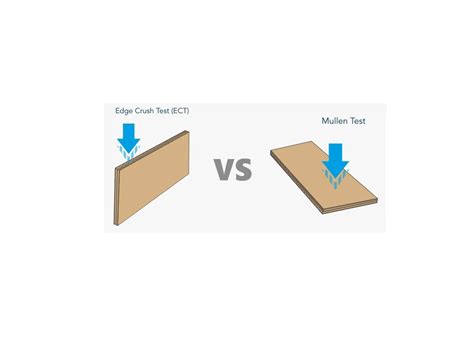

When determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in pounds and is related to the handling durability of the box material.

A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related .The fundamental difference between these two tests is that the Burst Strength Test requires a minimum basis weight of the paperboard. That is, the Burst Test requires that the base .

The Edge Crush Test rates how much weight can be stacked vertically on a box without damage and the Mullen Test rates how much force it takes to puncture a wall of the box. ECT rating is important to consider when stacking boxes, while .Compare the Edge Crush Test and Burst Strength Test to understand their role in packaging strength and durability for effective material selection.

Below is a chart that breakdowns different types of corrugated material and their corresponding bursting test and ECT rating, along with the maximum load per carton. The 32 ECT, 44 ECT, and 48 ECT are the most common box varieties, .A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a . This analysis aims to highlight the disparities between the Edge Crush Test and Burst Strength Test, offering guidance on when each test should be applied based on a company’s specific requirements. Learn about the history of corrugated strength testing and the two standard test in the industry: the Mullen burst test, and the edge crush test or ECT.

To measure box strength, two standard tests are commonly used: the Edge Crush Test (ECT) and the Mullen Burst Test. Both tests aim to evaluate the strength and durability of corrugated boxes but differ in their testing methods, .

Learn about the history of corrugated strength testing and the two standard test in the industry: the Mullen burst test, and the edge crush test or ECT. Skip to content (800) 642-1823 Edge Crush Test . Edge Crush Test, also known as ECT, is a testing procedure used to assess the durability of a box's edges. The amount of force that an ECT box can withstand before collapsing determines how highly .certification called ECT or Edge Crush Test. The ECT method was developed to provide a way to determine the “strength” of a corrugated box as it relates to stacking, or Box Compression strength (also referred to as BCT or Box Compression Test strength). ECT is a more appropriate measure than Burst when stacking strength is a primary design .

The Mullen Test measures the bursting strength of corrugated boxes. In other words, it tests the amount of pressure or force needed to rupture the wall of the box. Boxes that pass this standard are rated with the appropriate # or lb designation – 200#, 275#, etc. The Edge Crush measures the stacking strength of corrugated boxes or the amount .

systems. For example, while 32 ECT is an ALTERNATIVE to 200 Burst, 32 ECT is not EQUIVALENT to 200 Burst. In fact, we would expect that 200 Burst would test about 38 ECT and 32 ECT would Burst test at roughly 150. If your primary concern is crushed boxes nd stacking problems, consider specifying in terms of ECT. If it's a containment strength .Through certain testing methods such as the Edge Crush Test (ECT) and the Burst Strength Test, also known as the Mullen Burst Test, it is possible for companies to foresee these contingencies and design protective packaging according to their needs. In this context, it is common to face the dilemma between Edge Crush Test vs. Burst Strength. Although both the Mullen Burst Test and the Edge Crush Test, which are of great significance in gauging the strength of corrugated materials, they do not measure the same properties. The ECT determines a material’s resistance to edge or edgewise compression, which is vital in determining how well boxes can endure stacking and shipping pressures. ECT is often looked at by customers who are concerned about the max weight a box can stand during pallet shipments or warehouse stacking. The most common and universal boxes used today are 32 ECT. The Mullen Test measures the bursting strength or the force required to burst a hole through the corrugated material. This measurement is calculated .

The Edge Crush Test, which was developed in the 1990’s, measures the stacking strength of corrugated board – how much top to bottom pressure a box can withstand before crushing. Boxes conforming to the Edge Crush Test standard are identified as 32ECT, 44 ECT, etc. Again, the higher the number, the stronger the corrugated box.03 Defining Mullen Test vs. Edge Crush Test (ECT) Page 5 04 Strength Equivalencies of Mullen Test vs. ECT Boxes Page 6 . MULLEN TEST (BURST) EDGE CRUSH TEST (ECT) 100 lb 275# ECT-48 120 lb 350# ECT-51 140 lb 400# ECT-61 160 lb 500# ECT-71 180 lb 600# ECT-82 TRIPLE WALL CORRUGATED BOXES MAX LOADBoth UPS and FedEx require compliance with Item 222, including material specifications per package weight, dimensions and BMCs. Also, both require that the packages they carry are of minimum 200 burst strength or 32 ECT, and are capable of meeting appropriate International Safe Transit Association (ISTA) Pre-shipment Testing Procedures and .

rzr 570 compression test

Edge crush testing is good for determining a box’s stacking durability as well as the maximum weight it can carry. How does edge crush testing work? ECT measures the edgewise compressive strength of corrugated board by compressing a piece of . FedEx and UPS follow ISTA standards for packaging 30 pounds or less to be at least 32 ECT. 3 - Burst Test (Mullen Burst Test) The Mullen Test measures how much force is required to burst the main the force required to burst the corrugated board or paperboard.The Mullen Burst Box Strength Test measures the bursting strength of your cardboard boxes after pressure is applied. Basically, the Mullen Test determines how much pressure a box can withstand before it bursts or creates a hole. This helps see how much your box can hold and how much external pressure it can receive before becoming damaged.Packages must be in a minimum 200 lbs. Burst Strength or 32 Edge Crush Test (ECT) certified box. The box must also be of sufficient strength to protect the contents while in transit; or Any non-specification package that displays the ISTA seal indicating the package has been tested and certified to ISTA Procedure 3A is not subject to the .

The burst test takes into account the strength of the box even when it is being pressured from the side, and these shipping paths will exert more lateral pressure on the box over time. Anatomy of . For years the standard for corrugated packaging has been the ECT or Edge Crush Test. Edge crush slowly surpassed Mullen burst as the standard metric for corrugated strength. (Read more about ECT vs. Mullen Burst Here). The ECT value is then utilized to help calculate the “theoretical box compression strength” which is derived from the McKee . This changed the consistency of boxes and resulted in lower Mullen Burst Test ratings, but the vertical strength of boxes was still critical. To test this change, the Edge Crush Test was introduced. Understanding the Mullen Test. The Mullen test measures whether a box will arrive intact after disordered shipping and rough handling.

Also viewable in the seal is the Edge-Crush-Test or Burst-Test. Edge-Crush-Test (ECT) measures the stacking strength of corrugated cardboard boxes or fiberboard. Determining a finished box's compression-strength is defined by the amount of force that is needed to crush cardboard by standing it on its edge.Compare the Edge Crush Test and Burst Strength Test to understand their role in packaging strength and durability for effective material selection. +91 9313 140 140 . [email protected]. . Edge Crush Test (ECT): Imagine this as your cardboard's "toughness test". This ECT is an indicator of how capable a cardboard sample is in . The difference between a 32 ECT (Edge Crush Test) box and a 200-pound test corrugated box lies primarily in how their strength is measured and the type of performance they are designed to indicate.1. **Measurement Method**: - **32 ECT Box**: The Edge Crush Test measures the box's ability to resist crushing when force is applied to its edges. It assesses the .

The strength of shipping boxes is generally measured using edge crush test (ECT) for stacking strength or the Mullen Test for bursting weight. One of these two measures will be printed on any corrugated shipping box as part of its box manufacturer's certificate .200# Test vs 32 ECT (Edge Crush Test): 200# Test: 60% stronger bursting strength. Recommended by UPS for shipping up to 40 lbs. 32 ECT: Recommended by UPS for shipping up to 30 lbs. Pound Test Refers to Bursting Strength: 200# test boxes withstand 200 lbs/sq.in. of side wall pressure before bursting. ECT Refers to Stacking Strength: When you first see 200# and 32 ECT boxes, there may not be a noticeable difference between the two, but there are important differences between the two. Both the 200# and 32 ECT boxes are also commonly used for packaging - Read on to learn more! When you see or hear about the specification "200# Test" associated with packaging materials, it refers . But to understand the significance of that, it helps to also understand what a Mullen test (also called a “burst”) test is. Whereas an ECT measures the box’s top-to-bottom strength, think of the Mullen test like dropping a weight on the .

Mullen Test reports burst strength in pounds, i.e., 200#. A newer standard that has achieved widespread acceptance is the Edge Crush Test. The Edge Crush Test, or ECT, is a true performance test directly related to a box's stacking strength. ECT is a measure of the edgewise compressive strength of a corrugated board. ECT – Edge Crush Test. The Edge Crush Test (ECT) is a standardized laboratory test method that it is used to measure the cross-direction crushing of a corrugated board sample. To perform an ECT test, a force is applied perpendicularly to the specimen at a constant speed of 12.7 mm/min until it collapses.. The ECT is a true performance test and is directly related to .

ect vs burst strength

{{page.OGdescription}}

crush test ect vs burst strength ups|burst vs ect